This is just one example of General Stress Strain Gauges we have available at Sensors UK. Please contact us to discuss the wider options available.

General-purpose Foil Strain Gauges

The KFGS series gauges use polyimide resin for the base part that is approx. 13 μm thick. It ensures excellent flexibility. The outstanding moisture proof enables the KFGS gauges to operate in outdoor measurement effectively. Unless directly exposed to water drop, no coating treatment is required.

Applicable Adhesives and Operating Temperature Range after Curing

- CC-33A: -196 to 120°C (–10 to 80°C with vinyl-coated cable attached)

- CC-35: -30 to 120°C (–10 to 80°C with vinyl-coated cable attached)

- CC-36: -30 to 100°C (–10 to 80°C with vinyl-coated cable attached)

- EP-340: -55 to 150°C (–10 to 80°C with vinyl-coated cable attached)

- PC-600: -196 to 150°C (–10 to 80°C with vinyl-coated cable attached)

A strain gauge detects a minute dimensional change (Strain) as an electric signal. By measuring strain with the gauge bonded to a material or structure, the strength or safety can be known. Thus, the strain gauges are used in various industries including machinery, automobile, electric, civil engineering, medical, and food. The strain gauge are also adopted as sensing elements of force, pressure, acceleration, vibration, displacement, and torque transducers for various purposes including measurement and control of production lines. Kyowa produced the first Japanese-made strain gauge in 1951, and based on the abundant experience and technology accumulated for these years, the company manufactures a variety of high performance, environmentally friendly strain gauges.

Principle of Strain Gauges

If external tensile force or compressive force increases or decreases the resistance proportionally increases or decreases. Suppose that original resistance R changes by ΔR because of strain ε, the following equation can be set up.

Where, Ks is a gauge factor, expressing the sensitivity coefficient of strain gauges. General purpose strain gauges use copper-nickel or nickel-chrome alloy for the resistive elements, and the gauge factor provided by these alloys is approximately 2.

Types of Strain Gauges

Types of strain gauges are classified into foil strain gauge, wire strain gauge, and semiconductor strain gauge, etc.

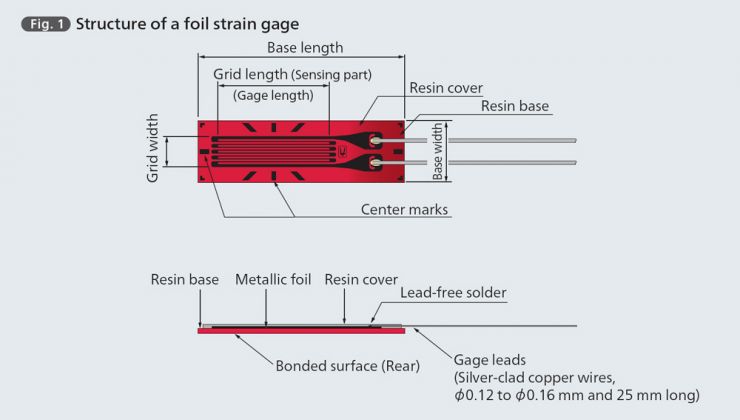

Structure of a Foil Strain Gauge

The foil strain gauge has metal foil on the electric insulator of the thin resin, and gauge leads attached, as shown in Fig. 1 below. The strain gauge is bonded to the measuring object with a dedicated adhesive. Strain occurring on the measuring site is transferred to the strain sensing element via adhesive and the resin base. For accurate measurement, the strain gauge and adhesive should be compatible with the measuring material and operating conditions such as temperature, etc.

Notes on pre-attached lead-wire cables

●Standard color of the 2-wire cable pre-attached to uniaxial gauges is red (R). If desired, a white, green, yellow or black cable can be pre-attached.

●Standard 3-wire cable pre-attached to uniaxial gauges has red stripes. If desired, the red stripes can be changed to blue or yellow stripes.

●In the case of a triaxial gauge, 2-wire cables are color-coded with red, white and green stripes for 0°, 90° and 45°, respectively and 3-wire cables, with red, yellow and blue stripes for 0°, 90° and 45°, respectively. The letter code is S in common.